Custom AI-Powered Manufacturing Solutions

GCN develops AI-driven solutions tailored to the unique needs of manufacturing companies. Our expert developers work closely with your team to build tools that improve production efficiency, optimize resource utilization, and streamline operations. From predictive maintenance to inventory management, we provide innovative solutions that help manufacturers reduce costs, minimize downtime, and boost productivity.

Areas of Expertise

GCN has successfully built AI-powered predictive maintenance systems that monitor equipment health in real time. By analyzing data from sensors and historical maintenance logs, these tools predict potential failures, helping manufacturers reduce downtime and extend the lifecycle of critical machinery.

Our developers have created AI-driven tools that analyze production workflows to identify inefficiencies and recommend process improvements. These systems help manufacturers enhance throughput, reduce waste, and meet production targets more effectively.

GCN specializes in building AI solutions for inventory and supply chain management that track stock levels, predict demand, and automate reordering. Our tools help manufacturers avoid overstocking, minimize waste, and ensure a seamless flow of materials through the production process.

Our team has experience developing AI-powered quality control systems that inspect products in real time using computer vision and machine learning. These tools identify defects, ensure consistent quality, and reduce the need for manual inspections.

GCN developers have worked on projects to design AI-based energy management systems that monitor and optimize energy usage across manufacturing facilities. These solutions reduce energy costs, minimize environmental impact, and improve operational efficiency.

Ai - Driven Solutions

Smart Robotics Integration

Digital Twin Technology

Customized Workflow Automation

Custom web & Mobile Apps

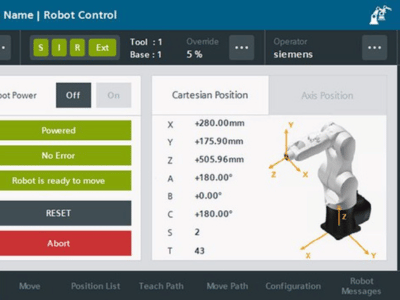

Factory Management Apps

GCN builds web and mobile apps that allow manufacturers to monitor production lines, track equipment performance, and manage workflows in real time. These apps provide seamless access to critical data from anywhere.

Inventory Management Apps

Our developers create inventory management apps that integrate with manufacturing systems to track materials, predict stock needs, and automate procurement processes. These tools ensure an uninterrupted production cycle.

Quality Assurance Portals

GCN has designed quality assurance portals that allow manufacturers to document and monitor product quality, streamline reporting, and ensure compliance with industry standards.

FAQs

GCN builds AI-powered predictive maintenance systems that analyze equipment data to predict failures, reduce downtime, and extend machinery lifecycles.

We’ve developed AI-driven tools that analyze workflows, identify inefficiencies, and recommend process improvements to enhance throughput and reduce waste.

Yes, we create AI solutions that track stock levels, predict demand, and automate reordering to minimize waste and ensure a seamless supply chain.

GCN develops custom workflow automation solutions that streamline tasks like scheduling, reporting, and resource allocation, improving efficiency and reducing errors.

Our developers build AI-powered quality control systems that use machine learning and computer vision to inspect products, identify defects, and ensure consistent quality.

GCN develops AI-based energy management systems that monitor and optimize energy usage across manufacturing facilities, reducing costs and environmental impact.

Digital twin technology creates virtual models of manufacturing processes. GCN builds digital twin solutions that allow manufacturers to simulate and optimize operations using real-time data.

We design AI-driven robotics solutions for tasks like assembly, material handling, and packaging, enhancing precision and efficiency in manufacturing processes.

Why Choose Us?

Rapid Deployment

If your business moves fast, we can match your stride. Our methodology allows us to onboard, design and develop your project as fast as you need it.

Affordability

With straightforward and transparent pricing, never guess how much your development bills will be. We make it affordable and easy to launch.

Growth Solutions

With over 20 years of experience, we've worked with clients to innovate or capitalize on the changing technology landscape. Don't get left behind with long development times and outdated technologies.

Frontend

React

Angular

JS

Bootstrap

HTML5

CSS 3

Backend

Java Spring

ASP.net

Python

Node

PHP Laravel

Infrastructure

AWS

Google Cloud

Azure

SAP

Docker

Kubernetes

Databases

DynamoDB

MS SQL

MySQL

GraphQL

Redis

MongoDB

Client Testimonials